Links to the other blogs of the Lighting 101 Series:

Lighting 101: Key Lighting Terms You Need to Know

Links to the other blogs of the Lighting 101 Series:

Lighting 101: Key Lighting Terms You Need to Know

Are LED Lights Considered Good for the Environment?

Yes, LED lights are better for the environment than traditional light sources as with proper heat management they can last much longer. LEDs deliver the same amount of lumens as traditional luminaires, but with less energy consumption. For example, a 400W HID luminaire can typically be replaced by a 150W LED luminaire and still deliver the same lumens.

Do LED Lights Burn Out?

Yes, all light sources will eventually burn out. However, LED sources typically last much longer than traditional light sources. They usually have a longer L70 rating. For example, a quality LED luminaire will have at least an L70 rating of 50,000 hours, while an HID luminaire may only have a rating between 6,000 to 15,000 hours.

Do LED Light Bulbs Save Money?

Yes, LED lights save money on energy consumption. They produce a higher rate of lumens per watt, meaning they are much more efficient and use less energy to produce the same amount of light.

What Does L70 Rating Mean?

L70 is a means of measuring lumen maintenance. The L70 refers to the point when an LED lamp source is producing 70% of its initial lumen output. For example, the RDA NTH-LED20 initial lumen output is 2089, its L70 rating is 100,000 hours. So at 100,000 hours the luminaire will be producing roughly 1462 lumens.

Why is this rating important when considering a luminaire?

This rating allows you to know how long you can depend on a luminaire to produce an acceptable amount of light.

Do LED Lights Produce Heat?

The short answer is yes, LED luminaires produce heat. The long answer is that while LED diodes produce heat, it isn’t where you might think. The heat is generated at the back of the LED chip. So, the back of the diode gets really hot, but the front/exterior of the luminaire remains cool to the touch.

In order to obtain long life, it is crucial to manage the internal temperature (junction temperature) of LED diodes. This can be accomplished in a variety of methods, one of the most common being the implementation of heatsinks to pull the heat away from the LED diode and disperse it.

What Color Temperature (CCT) is Best for Your Eyes?

Ideally, the best light for your eyes is that of natural light, which would be around 5000K and higher. Natural light boosts your vitamin D and has a tremendous effect on your circadian rhythm. In the absence of natural light, it is best to design the light to the needs of the space. For example, in an environment such as a doctor’s office or surgical room you would install a luminaire with 5000K or higher CCT for bright blue-white light – something crisp and clean. On the other hand, In a recovery room, you may want to step down to something 3000K to 2700K, that is more calming and cozy.

What luminaire is the right luminaire for my application?

This is all relative. In order to figure out the right luminaire for the application you have to consider the following:

Are LED Lights Dimmable?

Yes, LED luminaires can be dimmed provided that:

For example, some LED luminaires have a 0-10V dimming driver which would require a 0-10V dimmer. Others work off of ELV (Electronic Low Voltage), in this application you would use an ELV dimmer.

Can I use LED lights outdoors?

Yes, LED luminaires can be used in outdoor application ratings provided they have the appropriate IP or UL rating. For outdoor applications, the appropriate IP rating could be anything from IP44 to IP68. IP65 rating should cover most outdoor applications. When using UL as a guideline for outdoor use, look for a damp (think lighting under canopies, soffits, etc.) or wet location rating. When in doubt, contact a professional for help selecting the right luminaire for the job.

Should I change my light bulbs to LED?

Yes, the benefits to switching to LED from traditional light sources have been addressed ad nauseam over the past 15 years. LEDs are more environmentally friendly, and typically have a longer lifespan than traditional light sources. They also save on energy and labor costs, and are easier to control than some traditional light sources, like HIDs.

DLC, DLC Premium

DLC certification is a utility based initiative and one of the most important lighting certifications that customers look for. Many organizations offer rebate programs based on meeting DLC standards on a variety of luminaires such as but not limited to wall light, flood light, ceiling panels and high bays. DLC certifications require you to comply with 3 main aspects to the lighting which are distribution, color and longevity. These aspects must be tested by an accredited laboratory to be DLC certified. Testing results are submitted directly to the DLC by the manufacturer.

Furthermore, DLC premium takes it a step further due to the fact that it requires higher efficiencies and an additional light depreciation metric which most often results in higher rebates. Instead of burning out like traditional light fixtures, LEDs dim or depreciate their output over time. The industry accepted lifetime for an LED is when it reaches 70% of its original input, also known as an L70 projection. DLC Premium would require a L90 projection, which is when the fixture is expected to lose 10% of its output. Currently, DLC is in its 5.1 phase.

Notable RDA products with DLC Premium lighting certification would be RHB-LED, HELIX-LED, WP-LED and many more!

UL Certification

UL stands for Underwriters Laboratories, UL standards are employed throughout many industries to assure specific product performance and safety. If a luminaire has a UL marking along with a control number, it means it has met all safety requirements for that specific environment. There are 3 main UL markings, dry locations, damp locations and wet locations. Products with dry locations certification are typically used indoors and above-ground rooms, such as bedrooms, kitchens, offices, retail stores. It is the most common certification amongst lighting and it is also known as UL Listed within the industry.

Damp Locations Rated

Damp locations certification is approved for lightings that are regularly exposed to moisture and condensation. However, it is important to note that your luminaire can only handle a limited amount of water exposure which means that it cannot be directly exposed to snow or rain. Main applications for this marking would be outdoor usage with some coverings such as patio or perimeter of stores.

Wet Locations Rated

Wet locations rating means that the fixture can essentially be installed anywhere and has minimal limitations dealing with liquid as this rating allows the luminaire to come in direct contact with most types of liquids. If the product is UL listed, it indicates that the product has been tested to meet the safety standards of the United States by Underwriters Laboratories. While cULus indicates that the product has been tested to meet the safety standards of Canada and the United States by Underwriters Laboratories.

ETL

Similar to UL, An ETL certification means that products have been tested to set safety standards. ETL has 24 different marks/certifications to indicate anything from safety to health and environmental benefits.

A product bearing the ETL Listed mark with the “us” identifier at the 4 o’clock position has been tested and deemed compliant to U.S. product safety standards only. An ETL Listed mark with a “c” identifier at the 8 o’clock position means the product bearing it complies with Canadian product safety standards only. And an ETL Listed mark with both “us” and “c” identifiers at the 4 o’clock and 8 o’clock positions respectively, signifies that the product bearing the mark complies with both U.S. and Canadian product safety standards.

UL and Intertek (parent organization of ETL) are some of the few NRTLs (Nationally Recognized Testing Laboratories), a third-party testing program overseen by the Occupational Safety and Health Administration. Main difference between UL and ETL is that ETL does not publish their own standards. Instead, they test components to established standards of other NRTLs such as UL, ASME and ASTM.

IP

IP known as Ingress Protection defines the level of protection for the luminaire against outside bodies like debris, dirt and different forms of liquid. The numbers that follow IP each have a specific meaning. The first number represents the degree of protection from moving parts, as well as the protection of enclosed equipment from foreign bodies. The second number indicates the protection level that the enclosure enjoys from various forms of moisture.

There are 4 common IP certifications amongst lighting, IP65, IP66, IP67 and IP68. IP65 suggests that the luminaire is “dust tight” and protected against water projected from a nozzle. IP66 indicates that it is “dust tight” and protected against heavy seas or powerful jets of water. IP67 highlights that it is “dust tight” and protected against immersion of water for 30 minutes at depths of 150mm – 1000mm. Lastly, IP68 is rated as “dust tight” and protected against continuous submersion in water.

Hazardous Locations (UL884)

It is locations where explosion or fire hazards exist due to the presence of flammable gases, flammable or combustible liquid-produced vapors, combustible dusts, or ignitable fibers. Hazardous Locations are classified by the likelihood of an ignitable concentration of combustible material being present. There are two systems in place, including the traditional North American Division system as well as the alternative Zone system.

UL844, explosion proof lighting for Hazardous Locations–is one of several lighting certifications used in conjunction with National Electrical Code Classes, Divisions, and Groups of atmospheres for the selection of fixtures for normally and not normally hazardous locations where volatile flammable liquids, flammable gases, and combustible materials may be present in the atmosphere. Common examples of hazardous locations that require luminaire would be sawmills, grain silos or waste water treatment plants.

We previously covered this certification more in-depth in our 3-part blog series of

Lighting Challenges in Hazardous Locations!

NEMA 4X

NEMA stands for National Electrical Manufacturer Association. NEMA ratings are standards to justify the environment that the electrical fixture can be used in are mainly applied to fixed electrical enclosures. There are many NEMA ratings for different circumstances but the one we employ for our luminaires would be NEMA 4X. NEMA 4X highlights that the luminarie is suitable for Indoor or outdoor use primarily to provide a degree of protection against corrosion, windblown dust and rain, splashing water, hose-directed water, and damage from external ice formation.

Shoutout to Ed Wynne of RDA Lighting for his expertise throughout blog!

When purchasing any type of luminaire, Lumen is a crucial lighting term to look for, as it helps the user to understand and choose the most suitable one. It measures the light output from a luminaire, with higher lumen translating to having a brighter fixture and lower lumen translating to a dimmer fixture.

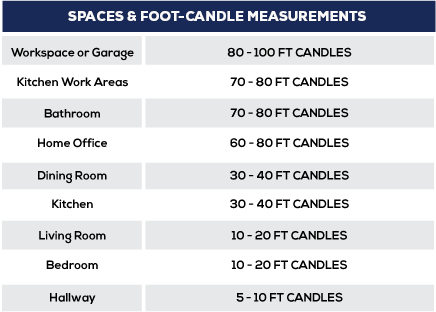

You can determine a rough estimate on how much lumens you need through calculating the square footage of the area, then multiplying that number by a universal foot candles measurement for different common residential and commercial settings:

For example, if you have a 100 sq ft. bedroom then you would need 1000-2000 lumens (100 x 10, 100 x 20).

A fun fact about lumen is that for every square meter on earth, the sun puts out 127, 000 lumens. A word of advice from RDA, do not look at the sun directly unless you have adequate eye protection.

Wattage is another common lighting term that shows up in all luminaires. It is the amount of power required for the luminaire to produce the lumen output. The higher the wattage, the more light it produces, however, with a higher wattage the operating costs for your luminaire increases. In most scenarios, you would want the wattage to be lower assuming your lumen requirement is satisfied. It is worth noting that Incandescent and fluorescent light sources would require more wattage to produce the same amount of lumens as an LED light source.

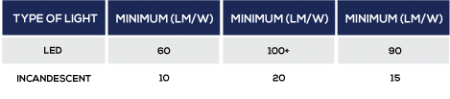

Light efficacy is a follow-up lighting term of wattage and lumens. It measures how well the light source produces visible light and it is calculated by lumens per watt. Most products typically have this measurement provided due to the increasing importance of efficacy nowadays. Nonetheless, it is still very simple to figure out light efficacy of a given product based on other measurements. Simply divide the total lumens produced by the luminaire by the wattage required to power it. For example, RDA ORA4-LED80 produces 8827 lumens and has input wattage of 78. 8827 divided by 78 gives an efficacy of 113 lumens per watt consumed.

The US Department of Energy believes that huge energy savings can be made by switching to LEDs, cutting business and homeowner electricity bills by $50 billion a year. With improved efficacy of lighting, the US is actually projected save 490 terawatt-hours of energy by 2035. This is nearly twice the amount of energy that the Energy Information Administration predicts will be produced by solar power in 2035.

According to the U.S. Department of Energy, cool white LED lighting products can produce 60–92 lm/W, compared to 10–18 lm/W for incandescent bulbs and 35–60 lm/W for Compact Fluorescents (CFLs). However, low-quality LED lighting products that are not designed properly may be no more efficient than incandescent bulbs.

The lighting term voltage represents the pressure from an electrical circuit’s power source that pushes current through a conducting loop enabling them to power devices. There are two types of voltages- Alternating Current (AC) or Direct Current (DC). Alternating Current alternates between positive or negative polarities hence the name, while Direct Current always has the same polarity, being either negative or positive. The most common Alternating Current voltages in regards to lighting are 120, 240, 277, 347 and 480. 120-277V and 480V are typically what RDA offers in most of our luminaires. An everyday example of DC voltage would be a battery and most often DC voltages in lighting are 12 and 24.

Other common terminologies would be line voltage and low voltage. Line voltage is the amount of voltage which a power line delivers to its destination or the point at which it is being consumed and in lighting this would be regarded as AC voltage. In North America, 120V AC is what is most frequently used in residential applications, 277V is typically used in commercial applications and 347 or 480 would be applied in industrial applications. Lastly, low voltage is typically defined as 50V or less and in most lighting applications low voltage would be DC voltage. Examples of lighting applications for low voltage would include landscape lighting or under cabinet lighting.

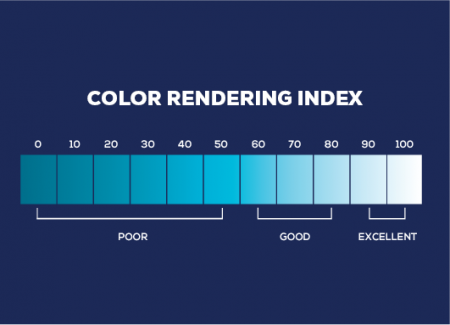

CRI is the measurement of the quality of how colors look under a light source, compared to how they would look under sunlight. The index ranges from 0-100, with 100 indicating that the colour would look the exact same under this light source as it would the sun – a perfect match to natural light. A general rule of thumb is that the higher the CRI rating is, the better the colours will look under a luminaire. This rating is important to consider when planning for retail or museum applications, when specific lighting that brings out the best of what it lights up is the key to success.

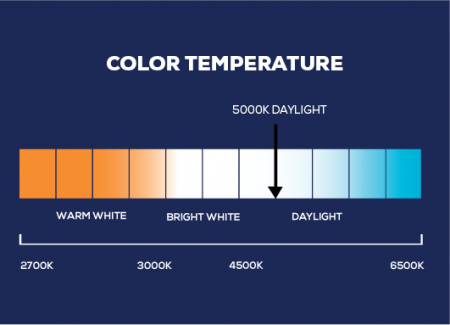

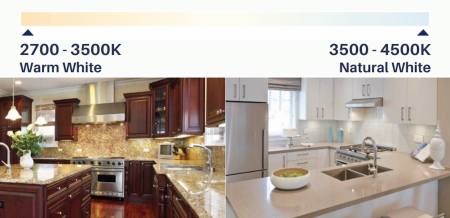

Color temperature describes a light’s appearance from a light source. This lighting term is very often referred to as Correlated Color Temperature (CCT). CCT is measured in degrees of Kelvin (K). For most lighting applications, it will range from 2700K to 6500K. The lower the CCT, the “warmer” or more yellow the appearance of the light source will be. On the other hand, the higher the CCT, the “cooler” or more bluish the appearance of the light source will be. For context, it is commonly accepted that 6500K is the best Kelvin temperature to match natural daylight.

It is very important to keep color temperature in mind when planning lighting for different applications. A warmer color temperature will create a more cozy, inviting space, while a cooler color temperature will feel brighter and more energizing. An office space, for example, is more likely to have cool, bright color temperatures, while an evening restaurant is more likely to have warmer, cozy color temperatures. Another example to consider is different kinds of shops. A jewelry store would ideally have very bright, cool temperatures to enhance the already-sparkling diamonds they sell. This could be around 5000K. On the other hand, a butcher shop would be more likely to have a warmer color temperature to bring out the freshness of the meat.

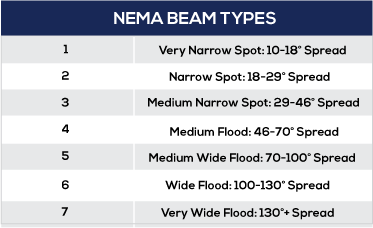

Light Distribution is the projected pattern that a fixture will disperse onto a surface. There are two commonly recognized standards for light distribution types – NEMA Distribution and IESNA Distribution. Looking at NEMA Distribution, this defines a luminaire’s light distribution by its horizontal and vertical beam spread. These patterns are well-suited for defining flood and sport light applications. There are 7 NEMA beam types:

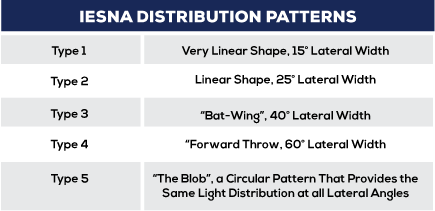

On the other hand, IESNA Distribution patterns define a luminaire’s light distribution more specifically by the shape of the area that is lit by the luminaire. These distribution patterns are typically used when designing with area or roadway lights. There are 5 IESNA beam types:

A special thank you to Ed Wynne of RDA Lighting for his expertise putting this blog together!

Technological advances in LED lighting have made it possible for lighting OEMs to offer more flexible LED luminaires that are lumen adjustable and CCT selectable. The additional flexibility and convenience of these luminaires is not only beneficial to Electrical Distributors, but to Contractors, Building Managers, and End Users as well. Take a look below at some of the details we’ve discussed to learn about how adjustable lighting is the future of LED lighting.

“As a distributor, we are always looking for stocking products that serve the most customers, at a competitive price point. Today, with wattage and selectable color LED technology, we can stock one SKU, instead of 4-8 different SKU’s. Not only does this save the distributor cost and valuable shelf space, but allows the customer to service their end user with one product. Regardless if the end user is a commercial office building, school, or residential homeowner, these products will cover their needs without the hassle of selecting individual wattage and color temps at time of purchase. One SKU, multiple options is a win-win for the distributor and their customers.” – Kevin Chandler at Rexel Lexington

One Lumen Adjustable and CCT Selectable SKU could replace many existing dedicated LED Lighting SKUs, thereby reducing the complexity that comes with ordering, managing, and database maintenance for multiple SKUs, as well as saving space in warehouses and showrooms for other products.

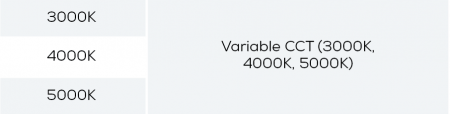

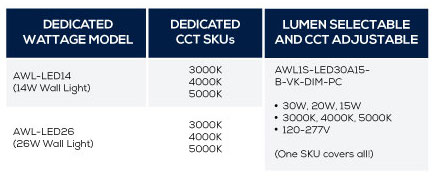

In the example below, a CCT Selectable sku brings the SKU count down from 3 to 1.

When we add Lumen adjustable luminaires to the equation, the SKU count is reduced even further from 6 SKUs in the dedicated option, to just one.

To satisfy a diverse range of local demand for LED Luminaires, a typical electrical distributor would need to carry multiple wattage and CCT options for a product. With constantly changing customer needs, this can lead to dead inventory sitting on the shelves. You may be stocking lights that customers won’t want in the future.

With more flexible luminaires, an electrical distributor is able to satisfy demand for multiple jobs, meeting a variety of needs without taking on the additional risk of having dead inventory.

With a range of customer needs and opinions, a contractor needs to ensure that they are carrying a light with the exact voltage, wattage, and color temperature that a customer is looking for. Once you arrive at a job with a luminaire to install, a customer may change their mind, and you deal with the problem of, “do I have the right sku they’re looking for in the truck with me?” or, “do I need to go back and order a different sku for this customer?”. It can be time consuming to worry about going back and forth to pick up a different sku. This is why, with an adjustable luminaire, back and forth is significantly reduced, as you have a large range of skus all in one fixture that you’re carrying.

Along with less back and forth when helping a customer, you also provide them with an exceptional range of flexibility while installing a fixture. This is helpful for customers that may not know exactly which specifications they need, or what would look ideal in a specific application. For example, look at lighting in kitchens. For kitchens with earthy, wooden tones, a warmer color temperature works, while brighter primary colors and stainless steel appliances work well with a more natural white color temperature. This is just one of the many details that a customer may know nothing about before you as a contractor arrives to install the lights.

Adjustable lighting also brings with it the benefit of less maintenance over time. As customers’ needs change, there’s no need to spend the time and money to replace full light fixtures with different ones. With adjustable lighting, while some fixtures require the contractor to switch these settings within the housing, others have it placed on the outside for quick, accessible changes, and both of these options have no need for a new luminaire. With a simple flip of a switch, you can adjust the wattage or color temperature.

RDA’s AWLS-LED Adjustable Wall Light series was recently launched, offering adjustable “all-in-one” SKUs. With color temperature options for 3000K, 4000K, and 5000K, as well as 3 different wattage settings (30W, 20W, and 15W) all in one fixture, this single sku boasts 9 different combinations of settings. What would have been 9 different skus in the past is now offered conveniently in a single efficient luminaire.

These new and flexible lighting fixtures provide a range of benefits for both distributors and contractors, but how do they help end users – the people that see these lights above them everyday?

As the owner/operator of a building, lighting fixtures that provide various options for color temperature and lumen output are key assets to reducing maintenance needs, saving you time and money for years to come.

This is most easily explained with an example. Say, as a building owner, you lease out a building that is used as a store. The most recent tenants used it as a clothing store mainly targeted at teenagers, so they wanted dimmer, warmer colored lighting to create the atmosphere they were looking for. Now, new tenants have moved in who want to sell jewelry, so they need the brightest, whitest lighting possible to show off the sparkling diamonds. Instead of having to replace all of your store’s lighting with new, bright white lights, you simply need to adjust the switches inside each light fixture to match the new tenants’ preferences.

This essentially “future-proofs” your lighting, with no need to replace fixtures in order to meet different needs.

In industrial buildings and office spaces with different ceiling heights, different light levels are required to maintain uniform light distribution throughout a specific space. In order to conserve a consistent look using the same fixture, you can adjust the lumen output in different areas. For example, in a lower ceiling area you would adjust the settings to a lower lumen output, in order to match the look of a higher ceiling area.

Courtesy of Geoffrey Walling of RDA Lighting

Dimmers and other controls can add additional cost to your project and that can be a huge financial burden for many end users. However, once you go with a lumen and CCT adjustable product, it acts as an efficient and inexpensive lighting control system and you can throw all of your previous dimmers and high-cost lighting controls out the window. End users would now have full control over their luminaires, at a significantly lower entry cost.

As the tenant of a home or employee in an office, although you may not deal with purchasing lighting yourself, adjustable fixtures can still help to provide you flexibility and convenience on a day-to-day basis.

First of all, similar to the contractor’s side of things, when a fixture is being installed, you have the opportunity to see all your options and select which wattage and color temperatures you prefer in a specific setting.

Additionally, if you are looking to lower electric consumption to save on costs, you can simply have the lumen settings adjusted on the already-installed lights. Similarly, if you are redecorating and would like a light’s color temperature to compliment a new paint color, this is a simple adjustment to be made, rather than a full replacement.

So, why now? With constantly improving technology and cost-effective LED lighting, the question is why not now? Adjustable lighting is able to benefit every party involved in a number of ways, without increased costs or negative impacts on the environment.

In the end, regardless of who you are and when you use it, adjustable lighting provides the benefit of doing more with less. For distributors, this means reducing skus needed, which provides simpler management of inventory and demand. For a contractor, this means less back and forth and improved on-the-job flexibility, along with less maintenance in the long run. Overall, customers are provided with more flexibility in their lighting, while using less products.

Check out a few of our adjustable lights that we are proud to offer at RDA Lighting!

What started as a retrofit job turned into a much bigger opportunity thanks to RDA’s quality products and communication between Locust Electric Sales, Temple University Hospital, and RDA Lighting. Thus, it resulted in RDA arranging the perfect fit custom LED lighting solution for Temple University Hospital.

The ORA-LED is not the only product family with custom capabilities. You can find all the different options for a product on our website’s product page under the Features/Benefit and Spec Sheet/Resources section. However, just because an option is not listed does not mean we cannot do it. Bring your custom job opportunities to our dedicated Engineering team and they will sort out the custom requirements for your client.

Check out the ORA-LED series for your next job and see how it can exceed your needs! Visit our product page or contact us for more information.

With over 1000 active coal mines, the United States is one of the world’s leading countries in coal mining. LED light plays a critical role in assisting mining workers to perform their work safely by providing visibility of workspace tripping hazards. However, lighting in these environments isn’t completely straightforward. In order to determine the ideal luminaire for your mine application, we’ve put together some key challenges and risks to be aware of, and some ideal certifications to look out for when choosing a luminaire.

Shock, Heat, and Vibration

Mining environments are not friendly for your typical LED light, spaces are tight, and vibrations are frequent. Fixtures in mining applications must be tough, compact, and durable. Additionally, temperatures in mines can often reach over 40℃ when ventilation is not present. Only hazardous-rated luminaires are capable of functioning in these extreme temperatures.

Explosions

The most common cause of a mine explosion is a buildup of methane gas, combined with a heat source. Methane is a highly combustible gas, and depending on how much of it is present in the air, it may only require a small source of heat to spark an explosion. This makes it especially important to have reliable luminaires in mines, so a faulty circuit doesn’t spark a chain reaction.

https://www.mining-technology.com/mining-safety/coal-mine-explosion-kills-11-miners-in-colombia

There are strict regulations in place to specify the requirements of a hazardous location approved LED light due to the dangerous nature of mining. Look for luminaires with the following certifications:

Class I and Class II UL Hazardous Location Ratings.

Class I covers Explosive Gas Atmospheres and Class II covers Explosive Dust Atmospheres – both are relevant to mining applications. For mines, pay close attention to Class I Div 2 Groups B, C, and D (atmospheres containing flammable gas), as well as Group A (atmospheres containing Acetylene – a gas used in welding). A luminaire with these ratings has been rigorously tested to be safe to use in Explosive Gas Atmospheres (Class I) as well as Explosive Dust Atmospheres (Class II).

Consider RDA Lighting’s NMV-LED Non-Metallic Vaporproof fixture for your next job. The NMV is a tough, but durable luminaire that meets all of the above recommendations.

Lighting in Marine and Offshore environments can come with many challenges. We’d like to walk you through the environmental hazards you need to be aware of for your next Marine project, and how you can mitigate the risks that they may pose.

https://www.sailmagazine.com/cruising/waterlines-chasing-leaks-on-boats

Corrosion

Not every lighting solution is capable of withstanding the tough challenges present in a marine, or beach and lake environments. Both freshwater and saltwater corrodes metal over time, but saltwater expedites this process roughly 5 times faster than freshwater. Even if the luminaire is not directly exposed to water, the humidity of ocean air can cause metals to rust 10 times faster than in air with normal humidity levels. Corrosion can lead to malfunctions, frequent replacements, and unsightly luminaires.

Water Ingress

Water ingress is another issue that arises when waves and storms cause large amounts of water to frequently hit the luminaire. The combination of water ingress and rust will significantly increase the risk of premature failure and result to costly replacements. Choosing the right luminaire for a marine application will ensure it has the necessary durability and reliability, which saves you maintenance and replacement costs in the long-run.

To combat the harsh marine environments and the challenges they come with, you should look for a lighting fixture with the following requirements to ensure long-lasting performance with low maintenance.

Non-Metallic

A non-metallic luminaire is excellent at resisting corrosion, making it ideal for Marine environments. These luminaires typically have reinforced polycarbonate housing rather than metal.

UL Marine Listed

You will also want a UL Marine Listed mark on your luminaire. The UL Marine Listing guarantees that the luminaire has been rigorously tested and approved specifically for marine use. For these harsher environments, a luminaire needs more than standard wet location features to guarantee protection from moisture. A UL Marine Listed luminaire will ensure the fixture can withstand harsh marine conditions such as vibration, impact, water ingress, and salt-spray corrosion1.

NEMA 4X

Type 4X offers a superior level of protection from corrosion and extreme environments and is capable of withstanding hose-directed water. With a Type 4X certification you can be sure you’re getting a corrosion-resistant luminaire that provides protection against windblown dust and rain.

Consider RDA Lighting’s NMV-LED Non-Metallic Vaporproof fixture for your next job. The NMV is a tough, but durable luminaire that meets all of these requirements.

[1] “UL Standard for Safety for Supplemental Requirements for Luminaires for Installation on Marine Vessels.” ANSI/UL, December 4, 2000.

Selecting appropriate lighting that meets specific certifications is not only important for properly illuminating a space, but also for the safety of everyone using that space. Each environment comes with different challenges, so here are some tips when looking at luminaires for different agricultural applications.

Many agricultural lighting applications are hazardous locations that require a special type of luminaire. Here are some of the key challenges and specs to look for in a luminaire for these applications.

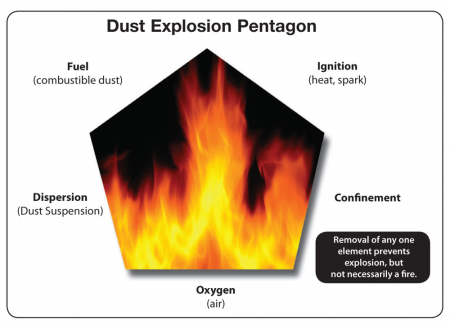

Dust Explosions

An uncommonly known fact about agricultural applications, like grain elevators, is that they are at high risk for explosions, given the right ingredients. These enclosed spaces are prone to the buildup of large amounts of dust suspended in the air. For example, grain produces dust when it moves. This combination of dust and air in an enclosed space creates a combustible mix that is flammable. When combined with an ignition source, an explosion can occur. Ignition sources could be anything from static electricity to a light switch, so using the wrong lighting could easily have devastating consequences in agricultural applications.

https://www.woodworkingnetwork.com/woodworking-industry-management/woodshop-safety-regulations/ComDust-What-Woodworkers-Need-to-Know-181234991.html

Hog Barns

With minimal ventilation and corrosive gases in the air, hog barns are also at risk for explosions or significant deterioration of materials within the building. As discussed in the Mitigation of Accelerated Deterioration of Pig Buildings, most of these buildings are completely enclosed for the pigs’ comfort, with a negative pressure ventilation system. Winter months significantly decrease the ventilation even further for warmth. This therefore increases a luminaire’s exposure to moisture and corrosive gases within the facility, pushing its limits to properly function.

Poultry Barns

Poultry barns are another environment in which you should carefully consider your lighting choice. They are similarly prone to dust buildups, but they are also often steam cleaned to remove bacteria and viruses. So, you would require a luminaire that can withstand this high pressure cleaning without issue.

There are many factors to consider in different agricultural spaces that could pose a danger, so this is why selecting a specific group of lighting fixtures for them holds a high importance in terms of your safety and others.

To greatly reduce the risk of dust explosion and provide peace of mind to your client, look for a fixture with the following certifications:

Hazardous Location Rated

We highly recommend using a Hazardous Location rated vaporproof – that is, completely sealed – luminaire, to prevent dust and dirt materials from entering and causing malfunctions or explosions.

UL844 Class II Div 2

One certification to look out for is UL844, specifically Class II Div 2 Groups F and G. This indicates that a luminaire has been evaluated and proven to safely withstand explosive dust atmospheres. By using a properly installed hazardous-rated lighting fixture, you mitigate the presence of a potential ignition source that could cause an explosion in these agricultural environments.

NEMA 4X

In terms of highly corrosive environments, like hog barns, or extreme conditions, like high pressure steam cleaning in a poultry barn, we recommend a luminaire that is NEMA 4X rated. This suggests that it has been evaluated and rated to withstand corrosion and extreme environments, preventing unnecessary problems with your lighting in the future.

Consider RDA Lighting’s NMV-LED Non-Metallic Vaporproof fixture for your next job. The NMV is a tough, but durable luminaire that meets all of these requirements.