Selecting appropriate lighting that meets specific certifications is not only important for properly illuminating a space, but also for the safety of everyone using that space. Each environment comes with different challenges, so here are some tips when looking at luminaires for different agricultural applications.

Many agricultural lighting applications are hazardous locations that require a special type of luminaire. Here are some of the key challenges and specs to look for in a luminaire for these applications.

The Challenges Presented

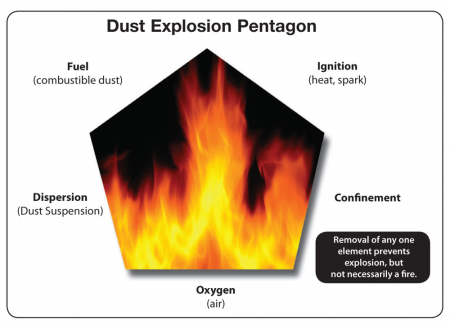

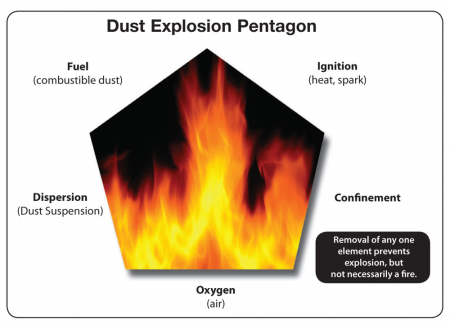

Dust Explosions

An uncommonly known fact about agricultural applications, like grain elevators, is that they are at high risk for explosions, given the right ingredients. These enclosed spaces are prone to the buildup of large amounts of dust suspended in the air. For example, grain produces dust when it moves. This combination of dust and air in an enclosed space creates a combustible mix that is flammable. When combined with an ignition source, an explosion can occur. Ignition sources could be anything from static electricity to a light switch, so using the wrong lighting could easily have devastating consequences in agricultural applications.

https://www.woodworkingnetwork.com/woodworking-industry-management/woodshop-safety-regulations/ComDust-What-Woodworkers-Need-to-Know-181234991.html

Hog Barns

With minimal ventilation and corrosive gases in the air, hog barns are also at risk for explosions or significant deterioration of materials within the building. As discussed in the Mitigation of Accelerated Deterioration of Pig Buildings, most of these buildings are completely enclosed for the pigs’ comfort, with a negative pressure ventilation system. Winter months significantly decrease the ventilation even further for warmth. This therefore increases a luminaire’s exposure to moisture and corrosive gases within the facility, pushing its limits to properly function.

Poultry Barns

Poultry barns are another environment in which you should carefully consider your lighting choice. They are similarly prone to dust buildups, but they are also often steam cleaned to remove bacteria and viruses. So, you would require a luminaire that can withstand this high pressure cleaning without issue.

There are many factors to consider in different agricultural spaces that could pose a danger, so this is why selecting a specific group of lighting fixtures for them holds a high importance in terms of your safety and others.

Lighting Requirements in an Agricultural Setting

To greatly reduce the risk of dust explosion and provide peace of mind to your client, look for a fixture with the following certifications:

Hazardous Location Rated

We highly recommend using a Hazardous Location rated vaporproof – that is, completely sealed – luminaire, to prevent dust and dirt materials from entering and causing malfunctions or explosions.

UL844 Class II Div 2

One certification to look out for is UL844, specifically Class II Div 2 Groups F and G. This indicates that a luminaire has been evaluated and proven to safely withstand explosive dust atmospheres. By using a properly installed hazardous-rated lighting fixture, you mitigate the presence of a potential ignition source that could cause an explosion in these agricultural environments.

NEMA 4X

In terms of highly corrosive environments, like hog barns, or extreme conditions, like high pressure steam cleaning in a poultry barn, we recommend a luminaire that is NEMA 4X rated. This suggests that it has been evaluated and rated to withstand corrosion and extreme environments, preventing unnecessary problems with your lighting in the future.

Consider RDA Lighting’s NMV-LED Non-Metallic Vaporproof fixture for your next job. The NMV is a tough, but durable luminaire that meets all of these requirements.