With over 1000 active coal mines, the United States is one of the world’s leading countries in coal mining. LED light plays a critical role in assisting mining workers to perform their work safely by providing visibility of workspace tripping hazards. However, lighting in these environments isn’t completely straightforward. In order to determine the ideal luminaire for your mine application, we’ve put together some key challenges and risks to be aware of, and some ideal certifications to look out for when choosing a luminaire.

The Challenges Presented

Shock, Heat, and Vibration

Mining environments are not friendly for your typical LED light, spaces are tight, and vibrations are frequent. Fixtures in mining applications must be tough, compact, and durable. Additionally, temperatures in mines can often reach over 40℃ when ventilation is not present. Only hazardous-rated luminaires are capable of functioning in these extreme temperatures.

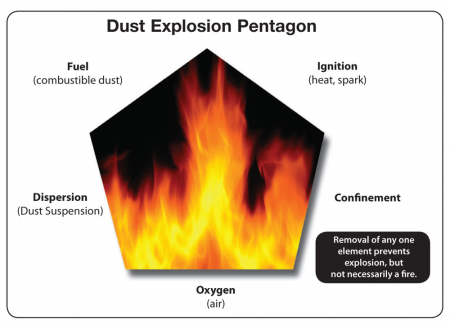

Explosions

The most common cause of a mine explosion is a buildup of methane gas, combined with a heat source. Methane is a highly combustible gas, and depending on how much of it is present in the air, it may only require a small source of heat to spark an explosion. This makes it especially important to have reliable luminaires in mines, so a faulty circuit doesn’t spark a chain reaction.

https://www.mining-technology.com/mining-safety/coal-mine-explosion-kills-11-miners-in-colombia

LED Mining Light Requirements

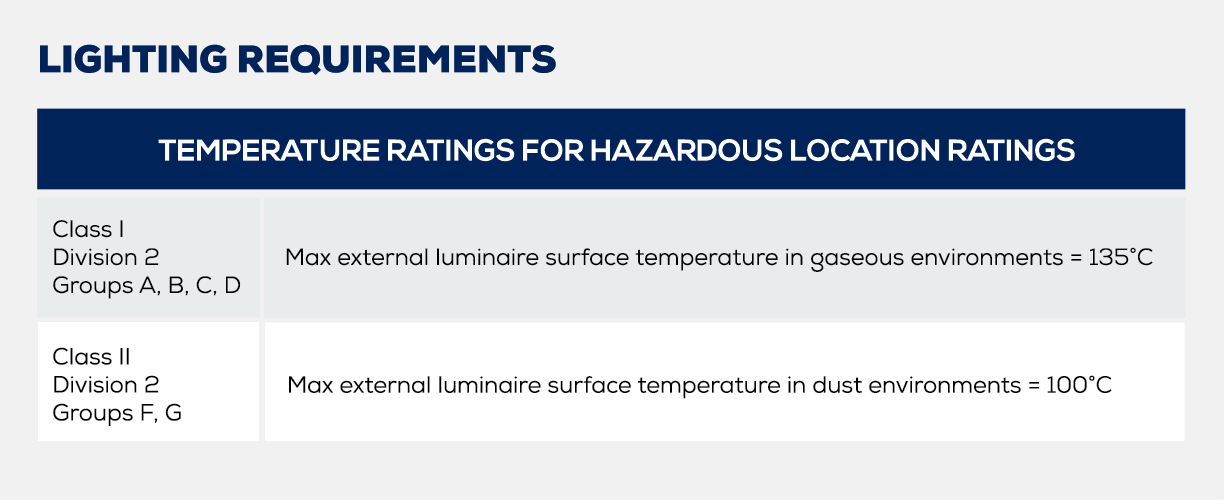

There are strict regulations in place to specify the requirements of a hazardous location approved LED light due to the dangerous nature of mining. Look for luminaires with the following certifications:

Class I and Class II UL Hazardous Location Ratings.

Class I covers Explosive Gas Atmospheres and Class II covers Explosive Dust Atmospheres – both are relevant to mining applications. For mines, pay close attention to Class I Div 2 Groups B, C, and D (atmospheres containing flammable gas), as well as Group A (atmospheres containing Acetylene – a gas used in welding). A luminaire with these ratings has been rigorously tested to be safe to use in Explosive Gas Atmospheres (Class I) as well as Explosive Dust Atmospheres (Class II).

Consider RDA Lighting’s NMV-LED Non-Metallic Vaporproof fixture for your next job. The NMV is a tough, but durable luminaire that meets all of the above recommendations.